I don't know what is going on. When my Rapman/Skeinforge system prints horizontal holes in objects they typically come out looking quite good. When I try to do an overhang, however, things start to go wrong.

Right now I am printing out the parts for jdavis' Sarrus linkage. There is a spine segment amongst the parts that looks like this.

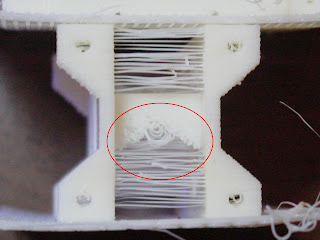

The center span has what looks like a relatively easy span. When I go to print it, however, it comes out looking like this.

I am pretty sure that there are some settings in Skeinforge that cure this up. Does anybody know what they are? Thanks!

2 comments:

"Infill in the direction of bridges" is all that I use. That only affects the flat bit of the span but it looks like yours goes wrong at the 45 degree slope. I am not sure why that would be.

Is this ABS or HDPE? I suspect HDPE would be less well behaved on overhangs.

Have you got a fan blowing on it? I get much better overhangs on the winward side than the leeward side.

BTW, why does it look like there is a raft on teh top as well as the bottom?

"why does it look like there is a raft on teh top as well as the bottom?"

That's because I leaned the part with attached raft up against another part with an attached raft so that I could photograph it.

I figured out what happened. I put a 0.3 extruder barrel on the extruder thinking it was 0.5. The filament pump is so powerful that it was happily pushing 0.5 flow rates out of the 0.3 mm orifice. When we got to an overhang the extuder was actually squirting filament into the void, which is why we got those cute little loops that you see in the picture.

I corrected the flow rates for 0.3 mm and now it does overhangs very nicely. Also cut it down to 0.25 mm layers. Very fine detailing. :-)

Post a Comment