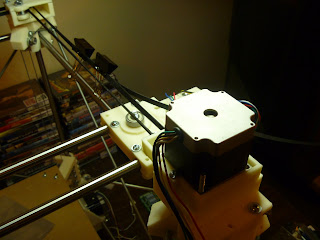

Darwin and it's direct derivatives uses two belt loops driven by a shaft connected to a NEMA 23 stepper.

In Sampo, that dual loop arrangement has been replaced with a single large loop

The belt guides are equipped with standard 608 skateboard bearings with printed fenders.

Topologically, the y-axis is simply an attenuated version of the x-axis.

8 comments:

Is your Y-Axis only driven one one side and the other side is dragged along?

Did you modify a BfB RepMan here?

What is the motivation for this change?

What behavior does it improve?

I must say that I never noticed any shortcommings with the Y as opposed to the Z axis.

PS:

Impressive spool of ABS in the first photo. ;)

Marcus asks all the questions I'd ask :) I also noticed the impressive spool of plastic...

Also, does this mean the print table is fully functioning now?

She is looking good..

Looking at the picture both sides of the Y axis are driven hence the long loop It travels down both sides.

So instead of twwo seperate belts it has one long belt.

Was half expecting this to be string as well not belt from the title.

Hence my deleted comment I looked and didnt read.. Opps...

@Marcus "Is your Y-Axis only driven one one side and the other side is dragged along?"

No, the x-axis assembly is supported on both sides.

"I must say that I never noticed any shortcommings with the Y as opposed to the Z axis"

Oh I agree, totally. I am mostly trying out a different configuration. The whole point of the Sampo development programme is to try out different approaches to how Darwin and Rapman do things. Some may be improvements while others may not. The way I've designed Sampo it is very easy to demount system and put another one on in its place. That is definitely not the case with either Darwin or Rapman.

In the case of the existing approaches of Darwin and Rapman to the y-axis, I found a few troubling aspects.

Both connect two short loops with a shaft. With Darwin's single shaft stepper you have to have the NEMA 23 extending well beyond the outside perimeter of the printer. Rapman solves this problem by using a dual shaft stepper.

In both cases, you require two pulleys and a stepper to shaft connector. I can't speak for Darwin, but Rapman uses a pair of 603 bearings. Those have to be special ordered and cost about $4/unit. As well, decent MXL pulleys cost about $10. You could depend on the shaft connector costing maybe $4. Specifying a dual axis stepper doesn't raise the cost much but really does reduce the number of choices you have.

My design uses 608 skateboard bearings, which can be had for as little as $0.30/unit and can be had for $1/unit at any sports shop. I use 6 of them. The two belts for the Rapman cost out at about $17.50 while the single belt for mine costs an additional $7.5.

So, for Rapman...

1x shaft - $2

1x shaft coupling - $4

2x 603 bearings - $8

1x 608 bearing - $1

6.67 ft MXL belt - $17.50

2x pulleys - $20

Total $52.5

For Sampo...

6x 608 bearings - $6

1x pulley - $10

10 ft MXL belt - $25

Total $41

The y-axis system for Sampo works just as well as that used on Rapman and Darwin and is cheaper.

More importantly, it uses considerably fewer KINDS of parts and only the MXL belt and pulley have to be special ordered and are typically sold by the same vendor. That conserves shipping costs. The rest can easily be had locally at decent prices.

I am betting that as more is sold the cost of MXL belt will drop dramatically. This has already happened with both steppers and stepper drivers.

@Chylld "I also noticed the impressive spool of plastic..."

I order full spools from New Image Plastics. That gets me $7.95/lb pricing and conserves on shipping. I do a LOT of printing. :-)

"Also, does this mean the print table is fully functioning now?"

It will be in a few days. I still have to print the mounts for the limits detector microswitches and the belt grippers for the x and y axes.

Wow - that's equivalent to AU$16.62 per kilo! I'm currently paying AU$69 per kilo for orbi-PLA :( (half of that is shipping)

Nice parts price list breakdown. I quiver at the thought of doing the same for my anti-wobble corners! (almost done, I promise)

I imagine if you were to pull it from one side, and have something elastic drag it back to the other. You could still have full control over the axis, but you'd also be able to add/remove extra pieces to the frame quickly. In order to make the axis longer/shorter.

Allowing simple upgrades to the build area when needed.

Post a Comment