Back in the late 1960s when I was very young and worked for IBM for a few years there was a magnetic tape that always lay beside the operator's console on the ancient IBM 360-40 computers labeled MULT. One day I worked up the temerity to ask the operator what it was and he said MULT stood for "many useful little things", viz, MULT. It was a compendium of utilities programmes that enabled the operator to maintain the old 360 and, given how reliable mainframe computers were in those days, was always kept very close at hand.

The projects that I've begun to undertake vis a vis Reprap reminded me of that old mag tape. Basically, I've been undertaking to explore technologies that might get the Reprap community into the next generation of Reprap machines. More to the point, I'm trying to crack some of the technical challenges posed by the Kartik M. Gada Personal Manufacturing Prize. Mind, I'm not looking to compete for the prize. The technical challenges, however, are very interesting.

Before the Gada Prize was announced, I was developing herringbone racks and pinions as a printable alternative to belts. Once the prize was announced, the 90% printed by volume and the 60 watt power limit specifications drew my interest. Prior to the prize announcement, I'd bought all the pieces to build up a heated bed for my Rapman 3.0 printer. It was obvious, however, that there was no way that a 3D printer with a heated bed was going to be possible using less than 60 watts.

At the time that I was thinking about all of this I was trying to develop a rail system to contain my herringbone rack so that I could use it to drive axes. I wanted to build a Delta Robot something along the lines that Festo had done.

The Festo Delta Robot uses lead screws in the three columns that seat the arms that move the extruder. I wanted to replace those with herringbone racks. I also wanted to make the columns printable. In that a usuable Delta 'bot is about a meter high, it was obvious that I wasn't going to be able to print a column in one piece. That put me face to face with the question of how to make a large piece out of a bunch of little pieces.

The conventional approach is to simply bolt the small pieces together. Frank Davies took this approach with his brilliant Sarrus Linkage positioning system.

Frank had avoided a lot of problems with printing larger parts by using relatively thin-walled, open structures. I shamelessly stole a lot of his techniques after having printed part of his Sarrus system. While thinking about that it occurred to me that you get relatively little warping if your part's biggest xy dimension is less than about 50 mm. Most of the parts I wanted to print had a cross section much smaller than that but were long and I needed them to be VERY accurate.

Then came the little epiphany. Why not rotate the long dimension to the vertical and leave the small cross-section on the xy print surface? Nophead {Chris Palmer} quite rightly pointed out that for a beam the extreme fibres on the upper and lower surfaces would be no stronger than the bond between two layers of printed plastic whereas if you printed the long dimension flat on the xy plane the bond between layers would only be subject to shear stress. In spite of that I began designing a columnar rail system for my herringbone racks and began printing it vertically, reasoning that a bending stresses would not be as severe in a column as in a beam.

After half a dozen false starts I finally got a design I liked. I rewrote the rack generation script for Art of Illusion so that it would put a flange on either side of the rack and then designed a cross-section that would seat racks on front and back sides. One of the racks would carry the drive pinion while the other would seat a pair of unpowered bogies to stabilise the positioning assembly.

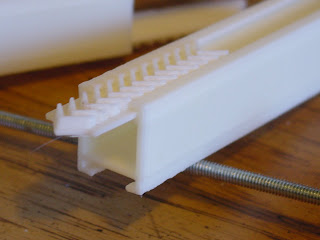

Here you can see a printing of a 100 mm long pair of these columnar rails.

Note that printing vertically allows you to create hollow structures, something much more difficult to do with present technology if you print them on their side. Also note how much like an extruded plastic or aluminum section this columnar segment looks. That was intentional. If some enterprising small Chinese factory starts paying close attention, it may be that this sort of section can become a very cheap vitamin instead of something that Reprappers in well served market areas have to print. That cuts down replication time dramatically.

I'd originally designed the column elements to test whether the rack prints fit properly. They did.

Before you start thinking that I'm some sort of design wizard, let me say that it took me four tries to get the fit right. This sort of design thing is very hard work for me.

That accomplished I was beginning to design the connection between the columnar segments when it occurred to me that the rack prints already did that.

What is nice about this approach is that you can simply slide rack segments into the column until it is full. I found as a practical matter that the segments dovetailed very accurately with just a touch of very fine grit sandpaper to knock off tiny bits plastic flash on the ends.

Just looking at the system one immediately realises that the join between segments is not what you would call a particularly strong. That is where an old trick I learned in architectural and structural engineering design eons ago came into play, viz, post-tensioning. In construction concrete is well known for being able to resist huge compressive loads but can resist virtually no tensile loading at all. Plastic, the way I was printing it vertically, as Nophead rightly pointed out, doesn't have good tensile strength and will, given sufficient load, fail in bending. In that way it is very much like concrete.

In building in concrete post-tensioning allows you to overcome this problem. The method is quite simple. You cast your concrete structure leaving channels through it. After it has hardened {cured} you thread tendons through these channels and then use hydraulic jacks to put the tendons in tension. The tendons are connected to either end of the beam you are building by face plates. The tensioned tendons, usually made of either high strength steel rod or cable, compress the concrete beam strongly via the end plates to which they are attached. Any bending forces put on the beam thereafter have to overcome this compressive force on the concrete before the beam can fail. The method is very widely used.

I printed up some end plates and cut a piece of #8 studding {4.2 mm threaded rod} for the tendon.

Here you can see the end plate and tendon in place.

Finally, I point loaded the resulting post-tensioned structure with a 750 gram Mag-Lite. The 200 mm column section weighs about 45 grams of which the steel and fixings account for 12-15 grams.

No visible deflection was observed. This beam in this orientation is 18 mm deep, mind, and the top and bottom membranes are 1.75 mm thick ABS. I will use this same approach for both columns and beams in the Delta Robot I am designing.

I think that by deepening the beam to 24-30 mm you could probably replace Rapman's 12 mm milled steel guide rods {and probably Darwin/Mendel's ... I haven't checked the exact specification} with a post-tensioned, virtually entirely printed equivalent using about 6% of the steel {#8} as is presently used.

Keep in mind that the #8 studding tendon is massively overdesigned. I bought #8 simply because, for some odd reason, it cost about on-third as much as #4 {2.8 mm equivalent}. Using perfectly adequate #4 studding would bring that steel fraction down to 4%. Heavens, even #2 would do the job!

One issue with this kind of development is creep, the tendency of plastic under stress to deform over long time frames. It may be that we are simply not loading plastic to anywhere near the stress levels where this becomes a problem. It warrants a hard look, however. Unfortunately, the reference manuals on plastics creep are quite expensive, viz, hundreds of dollars and are rather spotty in the coverage of plastic types that they discuss.

This blog is a lab notebook for my work with the Reprap open source 3D printing undertaking.

Sunday, January 31, 2010

Monday, January 25, 2010

Getting there with herringbone rack and pinion

I finally hit a break in my day job and after sleeping the clock around beginning Friday afternoon was able to get back to my Reprap work. I'd been working with herringbone rack and pinion design and had begun writing Art of Illusion scripts to generate this kind of technology. I'd done most of the rack script a few weeks ago, but I needed to be able to design herringbone gears a bit more efficiently.

Finally, on Sunday the scripts for the racks and gears began to come together. After a considerable amount of feeling around I found that I could reliably print an 8 mm radius, 12 toothed gear. Connecting such a pinion directly to a 1.8 degree step NEMA 17 gives me a 0.25 mm/ step on the axis without microstepping. I then designed a 32 toothed gear which let me get that resolution down to 0.094 mm/step. You can see the layout here...

The NEMA 17 turns the 12 toothed pinion at the top of the picture. It turns the 32 toothed gear which shares an axle with a second 12 toothed pinion which engages the rack. It's simple, easy and quick to print and doesn't backlash if you apply just a slight bit of compression to the gear train. My next task is to design a printable axis assembly to house it. My goal is to get rid of the skateboard bearings, too.

The scripts are in a lot better shape, but they're still not really ready for prime time.

Thursday, January 14, 2010

A printable, high speed alternative to belts?

Years ago, I created AoI scripts to design involute profile gears and racks. Recently, I've been exploring the notion of using rack and pinion drives instead of belts. While it is relatively easy to design and print a rack and pinion gear set, conventional ones have a problem with lateral stability.

I soon found that I was buying far too many skateboard bearings to make up for this problem than was sensible.

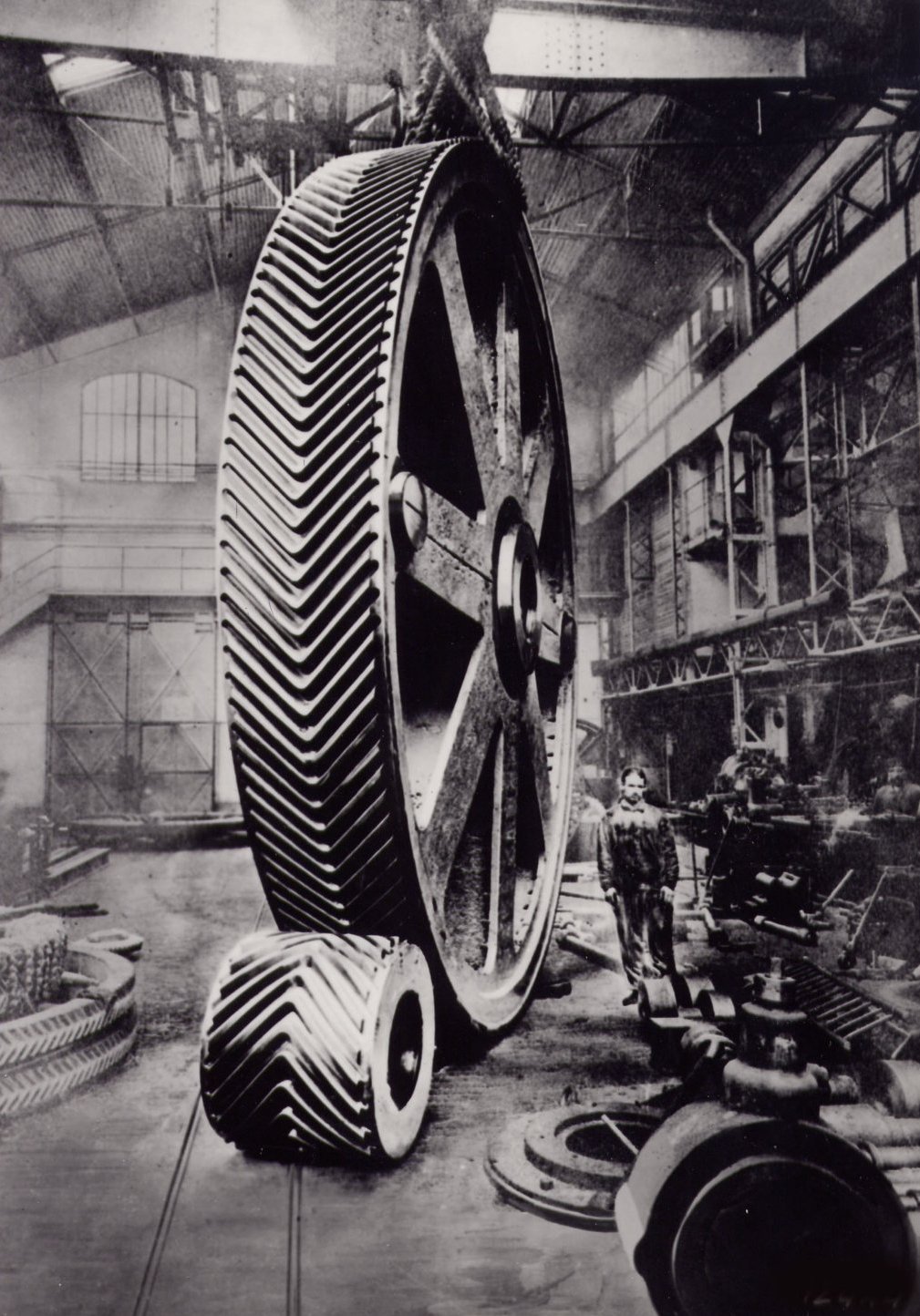

A month or so ago, I ran across the idea of herringbone {double helical} racks and gears.

You don't hear too much about this kind of gear and rack mostly because it can't be machined with conventional hobbing machines. It can, however, be printed relatively easily. I found that I could coax my extant rack and gear scripts to produce such components.

I was at, however, pretty much the limit of what Art of Illusion could handle. By the time I converted an involute gear profile or a rack to a triangle mesh then extruded and did a few boolean ops on it even the improved power of AoI 2.8 was barely up to the job.

While I could typically make herringbone gears happen the racks were a real trial. This had a bit to do with the fact that a rack profile does some really strange things when you apply AoIs triangle mesh routine to it.

You could extrude that and only get webbing on the outside surfaces. As you can see, however, you get lots and lots of triangles from AoI. I soon found that I could not make herringbone racks with more than about 12 teeth. It was easy to see with a rack that you ought to be able to describe it with relatively few triangles, so I gritted my teeth and decided to go directly to a solid description.

Using the Platonic Solids script as a point of departure, I began to develop a herringbone rack script.

I finally got the whole thing going during lunch today.

I checked the resulting STL in Netfabb and determined that it was perfect.

I developed a 12 toothed 10 mm radius herringbone rack and pinion pair.

This configuration gives you about 0.3 mm/step when you attach a 1.8 degree stepper to it. Gear that down by a factor of 3 using another herringbone gear pair and you've got the 0.1 mm/step standard Reprap resolution.

Herringbone gears are pretty much naturally anti-backlash. They seat firmly, are quiet and have strong lateral resistance. They're printable and there is no reason whatsoever why you shouldn't be able to use them instead of a belt. I printed up a 130 mm rack and pinion set this evening.

The racks can also, since they are very thin, be printed in long lengths without warping. Using a 0.3 mm extruder orifice and printing at about 16 mm/sec I completed the rack in about an hour and twenty minutes and the gear in 45 minutes.

I've been able to make rack and pinion sets with gear finenesses of 24 teeth for a 10 mm radius. That's really pushing the envelope, though. It appears that 20 teeth for 10 mm radius is a practical limit.

I intend to clean up the rack script and write one for the herringbone gears now that I know that they work well. I will make the scripts available as soon as I have them cleaned up a bit.

This experience has brought home what I consider a very important point for me. We need to be looking for technologies that aren't necessarily cheap or usual in metals. Such components are dependent on purpose built milling machines. Our printers are much more flexible than that. We need to choose technologies to print with that in mind.

Friday update:

I queued up a 267 mm rack while I was working this morning. No warping.

Not bad.

Sunday, January 03, 2010

A note to my old friend, Hitech.

Think about buying or building your kid one of these. It's an open source 3D printer. I bought mine from BitsfromBytes in the UK for about $1,200, mostly because I was in a hurry. You can build your own for maybe a third of that.

You can either buy the controlling electronics off-the-shelf.

... or ... if you want to get your kids into electronics, you can build up your own like I do at times. I tend to use stripboard for circuitry. You can get stripboards cheap out of New Jersey.

I use DIP though-the-hole chips because I'm old and clumsy. Little fingers can handle them a lot easier than you can with surface mount chips and components. I put together a layout app for design.

That makes getting from concept to board a lot easier.

Once you have your 3D printer working you can get your kids going designing and building THINGS instead of sketching things on paper or on some 3D CAD program.

I think there is a lot of potential for getting kids used to thinking in terms of solid objects and how things go together. One of the immediate applications is for kids to design and build their own robots. Robots tend to be team efforts at the kid level largely because there are parts that are expensive to make because you either have to have a machine shop or access to one. With a 3D printer you can simply print the fiddly bits.

Subscribe to:

Comments (Atom)