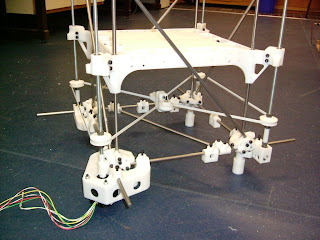

I had gone to considerable trouble to make sure that I sited the bolt holes in the MDF {medium density fibreboard} print table properly. To that end I designed a template for each of the brackets that would show me where the guide holes should be put.

Once I had the table suitably aligned, I was able to drill the guide holes with my Dremel tool quite easily.

I then removed the table and took it to the workshop to drill out the holes to #8 bolt diameter. When I returned and tried to mount the board I discovered that the holes didn't line up. I had neglected to mark the lower left corner of the print table and had no way of knowing which side our orientation matched my drilled holes. We are talking about a few mm here, mind. There were 16 possible orientations and that was complicated by the fact that the brackets were able to rotate around the z-axis linear shafts in the xy plane. After about the tenth possible orientation, I found one that fit 3 of the four brackets and just redrilled both the MDF and the bracket. Mercifully, solid ABS is very amenable to drilling so other than having the lower right corner showing an extra set of bolt holes, it all worked out quite well.

Hopefully, I will remember to mark the lower left corner the next time I build one of these. The print table moves quite freely as the video will demonstrate.

Now all that remains is for me to reprint the z-axis cable grippers and mount them and the z-axis will be complete.

Once I had the table suitably aligned, I was able to drill the guide holes with my Dremel tool quite easily.

I then removed the table and took it to the workshop to drill out the holes to #8 bolt diameter. When I returned and tried to mount the board I discovered that the holes didn't line up. I had neglected to mark the lower left corner of the print table and had no way of knowing which side our orientation matched my drilled holes. We are talking about a few mm here, mind. There were 16 possible orientations and that was complicated by the fact that the brackets were able to rotate around the z-axis linear shafts in the xy plane. After about the tenth possible orientation, I found one that fit 3 of the four brackets and just redrilled both the MDF and the bracket. Mercifully, solid ABS is very amenable to drilling so other than having the lower right corner showing an extra set of bolt holes, it all worked out quite well.

Hopefully, I will remember to mark the lower left corner the next time I build one of these. The print table moves quite freely as the video will demonstrate.

Now all that remains is for me to reprint the z-axis cable grippers and mount them and the z-axis will be complete.