This blog is a lab notebook for my work with the Reprap open source 3D printing undertaking.

Saturday, September 25, 2010

When ego takes charge

Nordom recently printed a brilliantly executed M30x70 bolt, nut and washer ensemble.

I was, of course, quite jealous of his accomplishment and still am. It is just a beautiful thing.

That got me to wondering, though, just how small a bolt one could print? As usual, I was too impatient to wait till Nordom got permission to distribute the STLs for his bolt and finally found something similar in Thingiverse.

I hate recessed head bolts so I replaced it with a regular hex head and scaled it down to a M10x20. After several tries I had something useful.

I've put it beside a similar metric bolt on the Rapman for scale.

Although the metric scale threads work in ABS, it seems obvious to me that something cut a bit deeper would be more useful.

Now that I've got that out of my system, I'll be going back to working on my carpal assembly.

Sunday, September 19, 2010

An interesting stringing behaviour

The ability to reverse the extruder on my Rapman printer during transitions between print roads has reduced stringing to an enormous extent. What stringing I do get tends to be very thin and feathery.

I've noticed an interesting stringing behaviour since the release of firmware version 4.0.2, though. You can see it here.

What you will get is a thin string between two objects being printed being propagated and then the string acting as a brush on th extruder orifice at intervals between roads. These brushed accretions build up into quite beautiful forms resembling frost.

When you get just a tiny bit of string hanging off of your print you will see the brushed accretion building up at 45 degree angles into something resembling fractal patterns.

This phenomena isn't a big issue for me. The accretions are thin and fragile and brush off easily without sandpaper.

They are pretty, though, in my opinion at least. :-)

Thursday, September 16, 2010

Dealing with detaching rafts

In which your narrator seems to have come up with a way to prevent raft peel for ABS on an acrylic print table.

About two weeks ago, the rafts for my ABS prints started detaching from the right hand side of my print table. I was losing one out of two to one out of three prints that way. At first I decided that my acrylic print table had simply got too warped and I had too much variation in level on the acrylic. I removed the acrylic print table and checked its flatness with a milled straight edge.

Indeed, it was a little warped so I used a belt sander on it till if was as flat as the milled straightedge. That seemed to work for about an hour but I was soon back to where I began. I then decided that the table was now adjusted properly and went to a great deal of trouble getting it so on my Rapman. Same result.

In desperation I began to print on the left hand side of the print table and the problem went away. It was still troubling, though.

On Tuesday, I finally caught on. In the last weeks the weather had cooled to where the outside temperature was in the teens more often than not and dropped into the single digits {Celsius} in the early mornings when I began to work. I looked at the printer table and noticed that the window I used to ventilate the work area was on the right hand side of the printer. The next time that I had a raft detach I measured the acrylic work surface temperature with my IR thermometer and discovered that whereas it was about 25-26 C on the left hand side of the table the draft from the window dropped that to 22-23 C on the right hand side. I was rather shocked that I got that wide a variation in surface temperature over a few centimeters distance, but I certainly did.

I closed the window and the peeling instantly stopped.

That remedy wasn't workable because of the ABS fumes, so I rigged a portable heat lamp onto my camera tripod to shine on the print table.

The radiant energy keeps the acrylic print table at 34-40 C with the window open.

I haven't had a raft detach since then. I've done a few dozen prints, mind.

Friday, September 10, 2010

Thursday, September 09, 2010

Acid test

I decided to give the new non-loop road finder routine a tough workout to see how robust it is. For that I designed a 20 mm diameter herringbone pinion gear.

I did a solid print for strength. As you can see, there were no problems. The stl's processed without drama and the gcode is good.

Wednesday, September 08, 2010

Changes to Slice and Dice

Slice and Dice was fine as long as your parts were more or less continuous along the z-axis and not so complicated that you got a lot of clashing with print loops. When I got to working on the thumb joint on my telepresence hand, however, I started having a lot of trouble with both of those limitations.

A major strength of Slice and Dice is that if you have a dodgy STL file you can clean up little imperfections on the slice images. That's wonderful until you have a part that you want to print that has little in the way of commonality between slices. I found myself fixing faults on 30-40 slices in Paint. That was seriously not fun. The main problem, as it developed, lay in the implicit dependence of Slice and Dice on looped road descriptions. Once you get into complicated parts it becomes very difficult to meet the app's expectation of clean looped print roads.

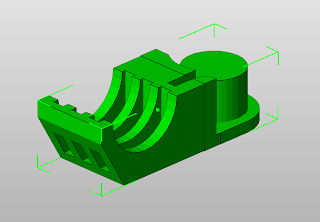

This is the part that started causing me trouble.

Virtually every slice is unique.

I rewrote the road making routine to deal with non-looped roads this evening. This is the resulting test print of the part shown above.

A problem that the old Rapman firmware was that it expected minimum print road line segments to be about 0.6 mm long. When I finished the rewrite, I was not looking forward to fitting line segments to the non-loop print roads. I had the output, but it was all 0.1 mm print roads.

Andrew at BitsfromBytes has said that the updated firmware would handle 0.1 mm roads with no problem. I frankly didn't believe him because the older firmware would slow the print down to 6 mm/sec with 0.1 mm roads. I decided to give it a try with the 4.0.2 code, however, and it turned out that Andrew is absolutely correct. The Rapman firmware has no trouble print sequential 0.1 mm line segments at my chosen print speed of 16 mm/sec.

That made the print file for the two halves of the thumb joint some 8 meg long. Since I have a 1 gig SD card, however, that's no trouble at all.

Monday, September 06, 2010

Wondering what the fuss is about

In which your narrator wonders what all the fuss is all about?

I guess I just don't get it. When you work with a plastic, after a while you get a feel for what it can do and what it can't. I started getting along along quite happily with no heated bed and ABS.

I print with a 0.3 orifice at an axis speed of 16 mm/sec. I suspect that I could kick it up to 22 mm/sec without a lot of drama, but I don't want to take the time out to play "who can print fastest" games at this point.

Once I started doing thin walled pieces and no infill my warping problems virtually disappeared. Most of the pieces I design have a largest dimension <= 90 mm though I've printed a herringbone rack that was 250 mm long. My acrylic print table temperature stays at about 25-30 degrees. You also don't find my prints warping after a few days from the internal stresses that Bogdan has talked about. I've seen that with HDPE. I was also printing with cross-hatched infill in those days, too.

I got into thin walled, no infill after I realised that if I went that way I got pretty fast prints that way at lower print head velocities.

Watching you guys reminds me of the first and second year architectural studio students that I used to lecture to back in my university professor days. They'd make models of buildings out of either "shipboard" {2 mm solid cardboard} or carve them out of expanded polystyrene foam treating it like it was so much cool butter or cheese. We used to say "form follows chipboard". If you followed the careers of those students they usually spent the first five years of their careers designing actual building that got built that looked as if they'd been carved out of cool butter. That's an extremely expensive way to design and build buildings. Those guys either got out of the habit fast or wound up doing architectural detail drawings for other designers who'd developed a feel and respect of the potential and limitations of the materials that went into their buildings.

Around here I see parts designed like you were more used to using an expensive CNC milling machine to carve parts out of a block of steel or aluminum.

That looks really cool but begs the fact that you're not taking advantage of the strengths and avoiding the weaknesses of the material you're working with, viz, plastic and extruded plastic at that. Somewhere along the line with Reprap we got the idea that we ought to be able to design parts in any shape we wished and whatever the material wanted to be be damned. You can see the trouble it's caused us in the chase after things like heated beds and support materials. We're spending a lot of time on that chase when we could be designing killer apps that make having a much simpler reprap machine very desirable.

That's just an old architectural technologist talking, I suppose.

I've included a link of the telepresence hand that I'm currently designing. That is human sized, btw. The largest part dimension is a touch over 80 mm. No warping whatsoever on any part.

Thin walled, no infill, snapped or glued together. There'll be a few screws in it to secure some elastic bands that return fingers to their rest positions. I haven't figured out how to secure elastics bands with snap on parts or glue yet. I'm thinking about how that might be possible all the time, though. :-)

Subscribe to:

Comments (Atom)